Conveyor Rollers

Conveyor rollers are critical components in the efficient functioning of conveyor systems, serving as the moving part that allows for the transportation of materials and products across a facility. These rollers provide the backbone for material handling operations, influencing the speed, direction, and load capacity of conveyor systems. When integrated into a conveyor system, rollers work seamlessly to facilitate the smooth and continuous flow of items, thereby enhancing productivity and operational efficiency.

+ Read more

The role of Conveyor Systems & Engineering, Inc. (CSE) is paramount within this industry. As experts in conveyor roller solutions, CSE delivers an array of products tailored to meet diverse industry needs, whether it’s gravity conveyors, powered conveyors, replacement rollers, gravity rollers, and beyond. Our specialization extends to crafting standard and custom rollers, ensuring compatibility and performance across various applications. We emphasize precision in roller dimensions, material selection, and bearing types, affirming their commitment to providing solutions that enhance the performance and longevity of roller conveyor systems.

+ Read more

CSE exhibits a combination of knowledge and experience that positions us as leaders in the conveyor roller market. With an understanding of the applications in different industrial environments, they engineer rollers that withstand the specific challenges of each application. Our capabilities cover the provision of rollers for light to heavy-duty usage, featuring a variety of constructions such as stainless steel, aluminum, PVC (plastic), and coated rollers, to provide distinct operational demands while upholding quality and reliability.

+ Read moreConveyor Rollers of Conveyor Systems & Engineering, Inc. are custom made. Use our online roller builder for new or replacement conveyor rollers 866-976-5537

Conveyor Roller Varieties and Applications

Conveying systems are an essential part of material handling in numerous industries, and conveyor rollers are central to the functionality of these systems. Types of conveyor rollers offered by Conveyor Systems & Engineering, Inc. include:

- Standard Rollers: These are typically used in simplistic roller conveyors for a variety of industries.

- Heavy-Duty Rollers: Designed for high load capacities, they are commonly found in industrial settings.

- Coated Rollers: Rubber or other coatings are used for extra grip and/or product protection.

For businesses searching for reliable solutions, we also offer a wide range of conveyor rollers for sale, ensuring that every project has access to durable and cost-effective components.

Advantages of Heavy-Duty Roller Conveyors

Heavy-duty roller conveyors are the material handling equipment you need for increased roll capacity. These conveyor sections are designed to tackle the toughest jobs in the industrial sector. Their robust construction and durability mean they’ll stand up to any job. Even gravity conveyors with heavy-duty rollers will make production more seamless and efficient.

These conveyors allow you to speed up loading and unloading. By reducing the need for manual lifting and handling, you will create a safer work environment while gaining increased productivity.

Heavy-duty conveyor rollers are built for the long haul, offering your operations a vital tool that can be customized to your needs. From the roller diameter to length and width, our conveyors are crafted from steel with care to have you covered every step of the way.

Although these heavy-duty rollers are an investment, they can quickly improve operations, making the cost worthwhile. Speed things up, protect your employees, and make your business grow exponentially by incorporating heavy-duty conveyor rollers to take on any tough jobs. Our expertise in building industrial roller conveyors ensures that your facility benefits from long-lasting performance, whether you require adjustable roller conveyor systems or standard gravity conveyors. Contact us today to learn more about having a heavy-duty roller tailored to your specifications.

Applications and industries that can benefit from conveyor roller systems are diverse:

Warehousing:

For moving boxes and containers through sorting and assembly lines.

Mining and Construction:

Where heavy-duty rollers withstand harsh conditions and heavy loads.

Industrial conveyor rollers are engineered to meet the rugged demands of industry operations, ensuring durability, efficiency, and safety.

Roller conveyors are chosen for their versatility and ease of integration into existing systems, making them a practical choice for businesses looking to streamline operations.

Manufacturing:

Automotive and electronics factories utilize conveyor rollers for parts assembly.

Food Processing:

Hygienic and easy-to-clean coated rollers are ideal.

From warehouse conveyor roller systems to conveyor frame and roller assemblies, our designs provide the flexibility needed for smooth integration into any operation. Finally, it’s imperative to source these components from reputable conveyor roller suppliers who can provide reliable equipment and support for your specific application needs.

Maintaining Conveyor Roller Systems and Your Conveyor Frame

Conveyor Systems & Engineering, Inc. stands out in providing premium quality and enduring conveyor roller solutions.

Quality and Durability

Conveyor Systems & Engineering, Inc. is committed to high-quality conveyor roller systems. Durability stems from the choice of materials and the precision engineering techniques applied during manufacturing. These rollers are designed to withstand the rigors of daily operation, reducing the frequency of replacements and maintenance interventions.

Maintenance and Servicing

Regular maintenance of all pieces, including the roller centers, is essential for maintaining the performance of conveyor roller systems. Conveyor Systems & Engineering, Inc., emphasizes the importance of routine inspections, cleaning, and lubrication to prevent common issues such as wear, misalignment, or damage. A systematic maintenance approach can significantly extend the lifespan of conveyor systems.

- Clean rollers to remove debris and residue

- Inspect for signs of wear or damage

- Check alignment and tension of the belt

- Lubricate moving parts as required

Additional Services

Beyond manufacturing, Conveyor Systems & Engineering, Inc., offers a suite of additional services to ensure their clients’ conveyor systems operate seamlessly. These services may include:

- Custom roller design

- Assistance in designing a system best suited for your application.

- Comprehensive after-sales support and parts replacement

1000 Series

The 1000 Series Sleeve Bearings Conveyor Rollers are designed for powered and gravity applications and are designed to be used without external lubrication.

Self-lubricating plastic resin bushings are proven to deliver a longer service life than lubricated rolling element bearings (ball bearings). In many cases sleeve bearings will outperform ball bearings in food handling, abrasive, high temperature, corrosive and wash-down applications.

Self-lubricating plastic sleeve bearings operate quieter and are relatively maintenance free, even in harsh environments.

Many of the plastic materials used in the 1000 Series Bearings are USDA and FDA approved.

Sanitary rollers are designed to prevent liquids or particles from entering the conveyor tube.

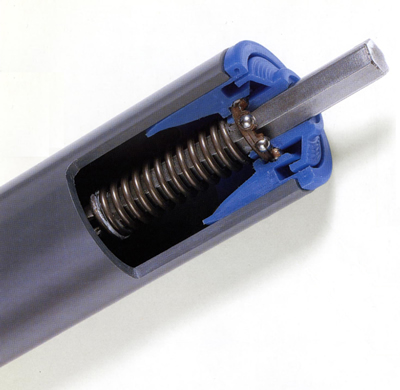

2000 Series

The 2000 Series Conveyor Bearings are designed for gravity and slow speed powered applications and are designed to be used without external lubrication.

Self-lubricating plastic resin raceway ball bearings are a cost effective solution in light duty and medium duty conveyor applications. The labyrinth seal prevents solid contaminants from entering into bearing raceways.

The 2000 series conveyor bearings are molded of either Delrin or polypropylene plastic resin. Material selection is based upon application.

Plastic ball bearings are relatively maintenance free, even in harsh environments.

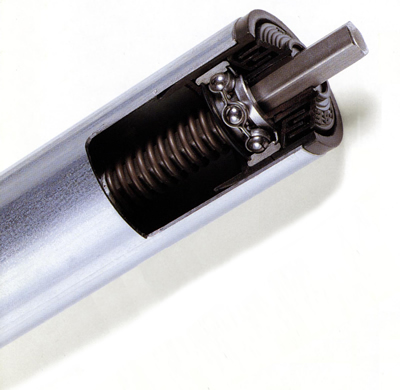

3000 Series

The 3000 series ball bearings are designed with metal raceways and metal balls. These bearings are typically described as rolling element bearings. These deep groove bearings may be supplied either with unground raceways (for gravity applications), semi-precision raceways (gravity or slow speed powered applications) or precision raceways (high speed and high load applications). The balls could either be retained with a ball retainer or full complement (no ball retainer).

The ball retainer can be of a plastic resin or metal design. The materials used for the 3000 series bearings can be chrome alloy or a variety of corrosion resistant stainless steels. They are designed for gravity and powered applications requiring higher

speeds and heavier load applications, however, metal raceway bearings have also been used for light and medium duty applications.

Labyrinth seals prevent solid contaminants from entering into the bearing housing. Depending on application, the bearings can be fitted with shields or seals to prevent egress of solid or liquid contaminants into the bearing raceway.

The 3000 series bearing housings are molded of a variety of plastic resins. All metal bearings are also available in steel or stainless corrosion resistant metals.

Reach Out to Our Team at Conveyor, Systems, & Engineering for Heavy Duty Conveyor Rollers and Roller Conveyor Systems

Our team of experts is always happy to talk. At Conveyor, Systems, & Engineering, we believe in the power of consultative selling. Our approach involves asking pertinent questions to understand your needs fully, ensuring that we recommend the perfect roller or conveyor solution for your specific application. What sets us apart is our dedication to empowering everyone involved in the process. We equip our team members with in-depth knowledge of our products, enabling them to ask the right questions and present themselves confidently in front of end-users. This ensures a seamless experience from consultation to implementation, where every interaction reflects our commitment to excellence and customer satisfaction. Whether you are exploring conveyor systems roller options for expansion or simply need durable replacements, we are here to provide customized guidance tailored to your industry needs. Contact us to learn more about our offerings, including conveyor rollers.

CUSTOM CONVEYOR ROLLERS

Delivering the Best Quality

Our rollers are engineered to the need of each customer to ensure the equipment received is correct for their application. Contact us today to let us know about your application and any issues you are facing with your roller conveyor system so we can offer advice to find a viable, long-lasting solution. Feel free to take a look at our news posts at the bottom of the page for some examples of where Conveyor Systems & Engineering, Inc. has overcome problems for previous customers.

Versatile, Customized Conveyor Systems that Last

Conveyor Systems & Engineering, Inc. present the most versatile conveyor system rollers to suit any application. Constructed using the highest quality roller conveyor system workmanship and designed to stand even the most rigorous use, our rollers provide function and utility that you can trust.

A Wide Range of Materials

Is corrosion an issue with your processing or manufacturing business? You should consider our plastic roller or one of our other non-corrosive options. If so, consider our pvc conveyor rollers, plastic conveyor rollers, nylon conveyor rollers, or stainless conveyor rollers.

We have the custom heavy duty roller conveyor system that you need. Conveyor Systems conveyor roller manufacturers can give you heavy duty conveyor rollers, steel conveyor rollers and durable industrial rollers. Many industries prefer our steel conveyor rollers for their unmatched strength and endurance, especially where heavy loads and rough conditions are involved.

A Wide Range of Applications

Do you need replacement conveyor rollers for your warehouse roller conveyors? Conveyor Systems conveyor rollers manufacturers offer cost-effective gravity roller conveyor, gravity replacement rollers. Maybe you need to move materials uphill. Our experts will guide you through the process of choosing the perfect conveyor roller for your facility.

Custom Conveyor Rollers

Your facility has unique needs, and as such, you need a custom roller conveyor system solution that will enable you to work at peak performance. You may benefit from our stock conveyor roller, but we have much more than this. Conveyor Systems & Engineering, Inc. has over 25 years in the business. We take many factors into consideration to deliver solutions which solve all your problems, including custom conveyor rollers with sprockets which are cost-effective and efficient.

Come to Conveyor Systems & Engineering, Inc. for All Your Needs

We help you find the best conveyor roller replacement equipment for your applications, and we also provide repair services. To find out more about our conveyor system rollers and the services we have to offer, call (866) 9-ROLLER today.

Increased Workflow Capacity

A busy warehouse facility requires robust solutions for maximum productivity. While labor costs and shipping times may be blowing out your budget, installing our high quality conveyor roller can dramatically increase your workflow capacity. By speeding up the processes that you use to deliver your goods by using high quality conveyor system rollers, you will see benefits in many aspects of your facility. From a reduced burden on your employees to meet demands, as well as a safer and more efficient workplace environment, you will see a higher level of customer satisfaction and most importantly, an increase in your bottom line. Our industrial rollers are trusted by leading companies to ensure continuous, efficient production, and they can be integrated seamlessly into adjustable roller conveyor systems for maximum flexibility.

Improved Safety Measures for Any Warehouse or Facility

Conveyor Systems & Engineering, Inc. is committed to providing the most safe and reliable rollers to suit any system or process in a busy working facility, whether the conveyor uses a gravity or powered mechanism of action. A strong and long lasting effect is produced through self-lubrication offered on many of our rollers. Suitable for a range of applications including food handling, chemical transport, volatile material movement and high capacity warehousing, our range of custom conveyor system rollers are backed by our service guarantee that ensures safe and efficient use in a consistent and durable manner. When considering long-term solutions, our warehouse conveyor roller systems combine durability with safety, giving facilities confidence in handling both light- and heavy-duty operations.

Frequently Asked Questions

We supply a full range of conveyor rollers, including gravity rollers, powered rollers, belt conveyor rollers, steel rollers, stainless steel rollers, and heavy-duty industrial rollers for all types of conveyor systems.

Most of our conveyor rollers are designed for universal fit and work with new or existing conveyor systems. Custom-fit solutions can also be manufactured.

Absolutely. We manufacture heavy-duty steel rollers built to withstand high loads, harsh environments, and continuous industrial operation.

Our conveyor rollers are widely used in manufacturing, packaging, distribution, warehousing, food processing, automotive, and material-handling industries.

Choosing the right roller depends on load capacity, roller material, operating environment, and conveyor type. Our team can help you select the best option for your application.

Yes. We specialize in custom manufacturing conveyor rollers in any size, diameter, material, or specification based on your system requirements.

Lead time varies based on quantity and customization, but we focus on fast manufacturing and quick shipping to minimize downtime.

Variable Speed Solutions for Precise Usage Requirements

No two facilities are created equally, and as such, Conveyor Systems & Engineering, Inc. provides a range of options that are specifically created to suit the speed at which you work. In particular, the 3000 Series roller conveyor system is designed for the most extensive precision requirements, offering gravity, slow-speed or high-speed application usage, while the 2000 Series offers specialized use for gravity and slow speed applications. With our range of options and commitment to providing a personalized and comprehensive design and implementation strategy, our rollers enable success and profitability for any facility setting.

Cost Effective Approach to Time Management

Implementing a robust conveyor roller solution to your facility need not be the expensive effort that it once was. Conveyor Systems & Engineering, Inc. offers the most extensive range of custom conveyor rollers designed to reduce your overheads while saving you time. By automating your in-facility transportation processes with stronger and loner lasting rollers, the initial investment on implementing your conveyor roller will save you money on labor costs. With a focus on durability and use within a wide range of applications, our rollers far outperform more expensive products.

Experience the Benefits of Conveyor Rollers

Installing high quality rollers to your existing conveyor can do wonders for your systems. Conveyor Systems & Engineering, Inc. provides a range of versatile solutions that increase efficiency, reduce noise and prevent wear of your system. Each of our roller series’ feature state of the art workmanship designed to increase the life of your system, regardless of the high use that it sees. Our experienced team can assist you with choosing the right type of roller for your existing conveyor equipment in order to maximize the productivity of your facility. Our range of options provide easy integration into any material transport system.

Replacement Conveyor Rollers

Conveyor Systems & Engineering, Inc. provides any conveyor replacement roller from custom conveyor rollers, conveyor parts, conveyor belt rollers, and much more. Visit our Online Roller Builder for completely customized experience for your replacement conveyor rollers.